Suitable for Chocolate and Caramel Enrobing

Suitable for Chocolate and Caramel Enrobing

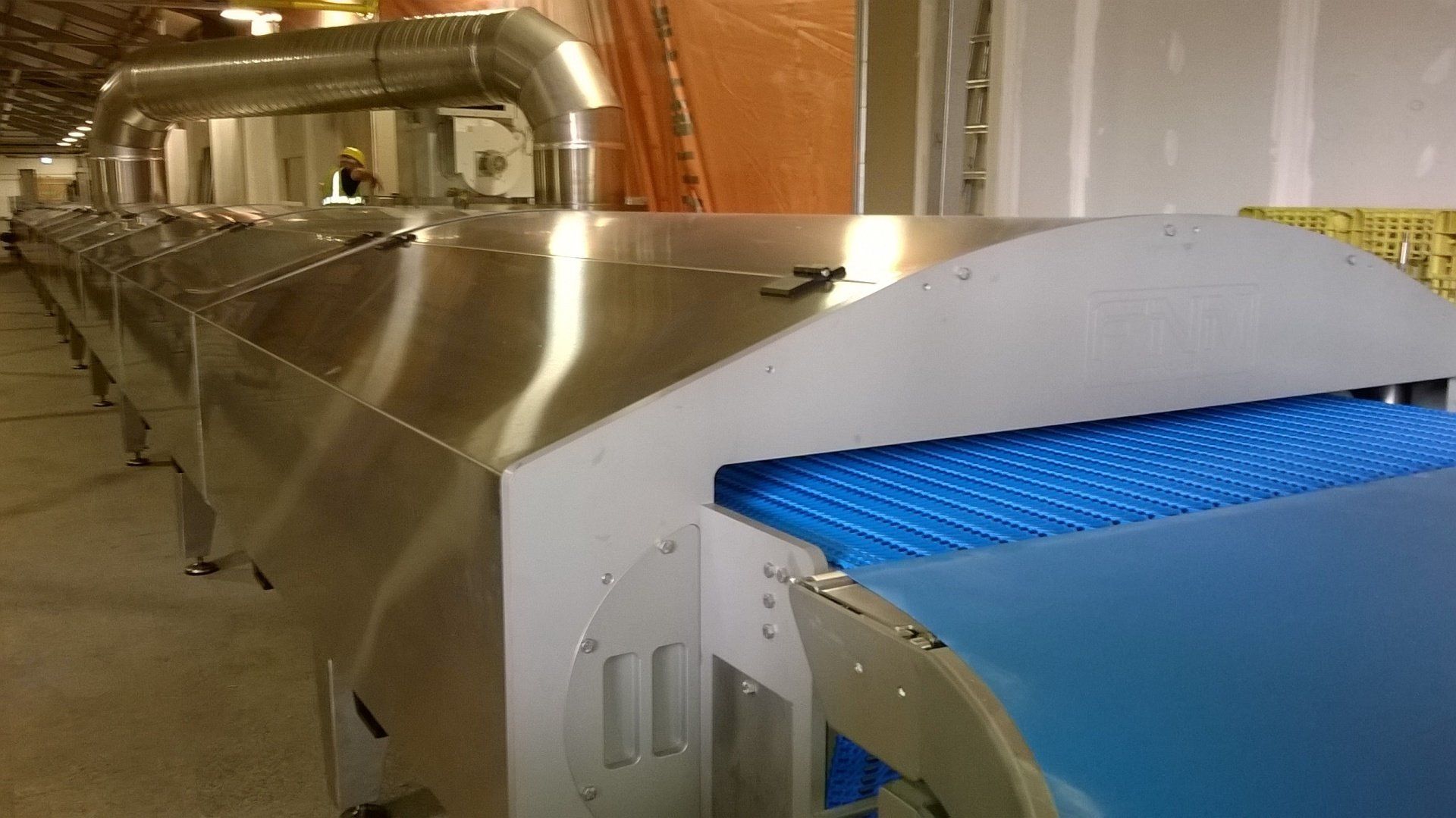

Stainless Steel Cooling Tunnels

Stainless Steel Cooling Tunnels

The MCE Cooling Tunnels are designed and built in the UK to serve the global food market with high performance, hygienic and easily serviced equipment.

The Hygienic Challenge

The Hygienic Challenge

Common with all MCE food process equipment, hygienic design is paramount. The Cooling Tunnel is constructed throughout in stainless steel with sloping surfaces so that it can be washed inside and out with a self draining design. Our built-in air cooling modules allow easy access for filter change and cooling coil cleaning whilst maintaining a 300mm floor clearance. Overlapping surfaces are minimised and traditioinal rubber or plastic sealing elements have been removed to eliminate any risk of food contamination from damaged seals. The ductwork carrying the high velocity TurboFlow impingement air is either hinged for better cleaning access or removable through the hinged access doors if detailed cleaning is required.

Value

Designed and made in the UK to the latest CAD/CAM manufacturing techniques in 3 metre modular lengths for accurate manufacture and quick assembly times. Process widths available include 400, 800, 1200 and 1600 mm to run at line speeds up to 20 m/minute. We offer different cooling techniques to suit different processes. Chocolate cooling is gently done by ContraFlow cooling air above and below the woven PU coated belt and can be temperature zoned to minimise temper damage, allowing stable Beta V crystal growth. High temperature foods and cooling rate insensitive products like caramel and licorice are cooled as rapidly as possible with TurboFlow high velocity impingement jets above and / or below the product with the option for pressurised water cooling below the belt. Our air cooling modules can be supplemented with desiccant dehumidifiers to provide surface drying of foods as well as temperature reduction.